Expo

Medica

view channel

view channel

view channel

view channel

Medical Imaging

AICritical CareSurgical TechniquesPatient Care

Point of CareBusiness

Events

Webinars

- Skin Patch Measures Effectiveness of Flu/COVID Vaccines in 10 Minutes

- Complete Revascularization Reduces Risk of Death from Cardiovascular Causes

- Tiny Fish-Inspired Robots Navigate Through Body to Deliver Targeted Drug Therapy

- Sweat-Powered Sticker Turns Drinking Cup into Health Sensor

- Coronary Artery Stenosis Could Protect Patients from Pulmonary Embolism Effects

- Optical Tracking Method Identifies Target Areas in Robot-Assisted Neurosurgery

- General Anesthesia Improves Post-Surgery Outcomes for Acute Stroke Patients

- Drug-Coated Balloons Can Replace Stents Even in Larger Coronary Arteries

- Magnetic Kidney Stone Retrieval Device Outperforms Ureteroscopic Laser Lithotripsy

- Absorbable Skull Device Could Replace Traditional Metal Implants Used After Brain Surgery

- VR Training Tool Combats Contamination of Portable Medical Equipment

- Portable Biosensor Platform to Reduce Hospital-Acquired Infections

- First-Of-Its-Kind Portable Germicidal Light Technology Disinfects High-Touch Clinical Surfaces in Seconds

- Surgical Capacity Optimization Solution Helps Hospitals Boost OR Utilization

- Game-Changing Innovation in Surgical Instrument Sterilization Significantly Improves OR Throughput

- B. Braun Acquires Digital Microsurgery Company True Digital Surgery

- CMEF 2025 to Promote Holistic and High-Quality Development of Medical and Health Industry

- Bayer and Broad Institute Extend Research Collaboration to Develop New Cardiovascular Therapies

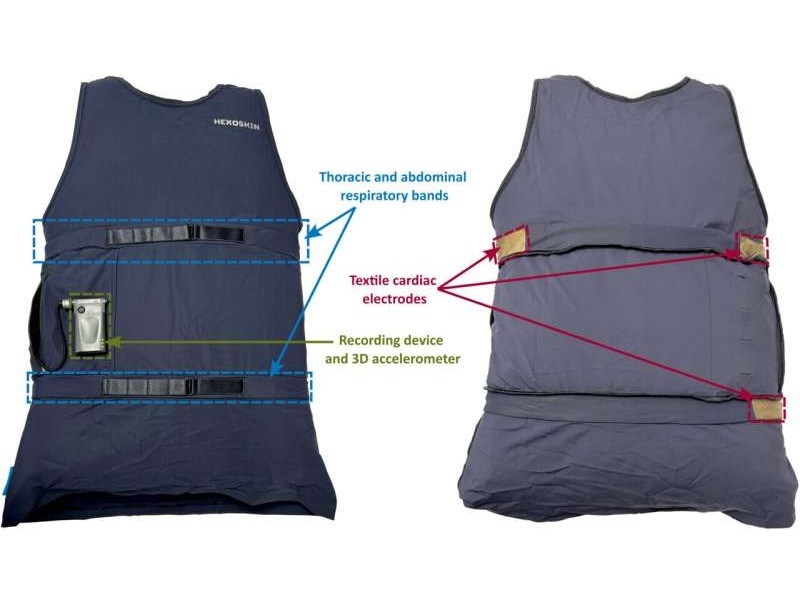

- Medtronic Partners with Corsano to Expand Acute Care & Monitoring Portfolio in Europe

- Expanded Collaboration to Transform OR Technology Through AI and Automation

Expo

Medica

Expo

Medica

- Skin Patch Measures Effectiveness of Flu/COVID Vaccines in 10 Minutes

- Complete Revascularization Reduces Risk of Death from Cardiovascular Causes

- Tiny Fish-Inspired Robots Navigate Through Body to Deliver Targeted Drug Therapy

- Sweat-Powered Sticker Turns Drinking Cup into Health Sensor

- Coronary Artery Stenosis Could Protect Patients from Pulmonary Embolism Effects

- Optical Tracking Method Identifies Target Areas in Robot-Assisted Neurosurgery

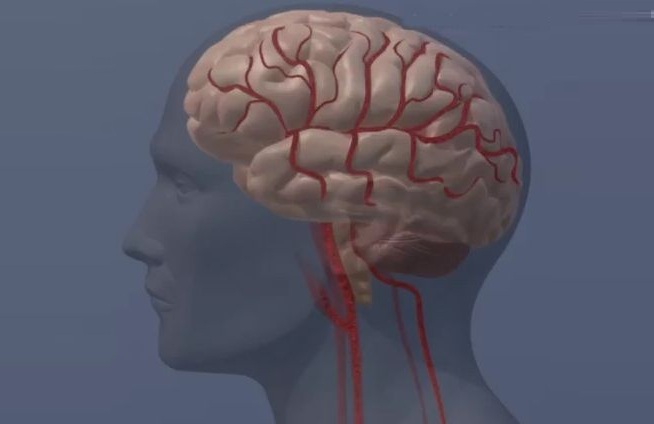

- General Anesthesia Improves Post-Surgery Outcomes for Acute Stroke Patients

- Drug-Coated Balloons Can Replace Stents Even in Larger Coronary Arteries

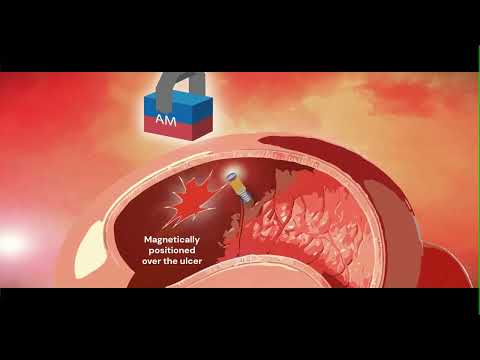

- Magnetic Kidney Stone Retrieval Device Outperforms Ureteroscopic Laser Lithotripsy

- Absorbable Skull Device Could Replace Traditional Metal Implants Used After Brain Surgery

- VR Training Tool Combats Contamination of Portable Medical Equipment

- Portable Biosensor Platform to Reduce Hospital-Acquired Infections

- First-Of-Its-Kind Portable Germicidal Light Technology Disinfects High-Touch Clinical Surfaces in Seconds

- Surgical Capacity Optimization Solution Helps Hospitals Boost OR Utilization

- Game-Changing Innovation in Surgical Instrument Sterilization Significantly Improves OR Throughput

- B. Braun Acquires Digital Microsurgery Company True Digital Surgery

- CMEF 2025 to Promote Holistic and High-Quality Development of Medical and Health Industry

- Bayer and Broad Institute Extend Research Collaboration to Develop New Cardiovascular Therapies

- Medtronic Partners with Corsano to Expand Acute Care & Monitoring Portfolio in Europe

- Expanded Collaboration to Transform OR Technology Through AI and Automation

- Richard Wolf to Present Innovative System Solutions at Germany Trade Show

- PROTEC to Launch New Motorized PRS 500 B X-ray System

- Randox to Showcase Future-Proofing Diagnostic Technology at Trade Fair

- NDS Announces New OR Networking Solution at Germany Trade Show

- Global Good and Motic Announce AI-Powered Microscope at MEDICA 2017

- Rober Showcases Pioneering ‘Zero Pressure’ Mattresses in Germany

- UK Companies Showcase Life-Saving Solutions at Medica 2018

- Siemens Healthineers Showcases ACUSON Ultrasound Product Portfolio

- Metaltronica Presents Digital Mammography Systems at Medical Trade Fair

- Canon Displays New Products at MEDICA Show

- Samsung Medison Exhibits New HERA I10 Combination Ultrasound System

- Medtronic Displays Patient Monitoring Systems at MEDICA 2019

- Healcerion Exhibits SONON Wireless Handheld Ultrasound at MEDICA 2019

- Hans Rudolph Exhibits Latest Range of Oro-Nasal Masks at MEDICA 2019

- EIZO Demonstrates CuratOR Alipe IP-Based Video Management Solution at MEDICA 2019

- Fisher & Paykel Demonstrates Humidified Nasal High Flow System for Delivering Respiratory Support at MEDICA 2021

- Axcent Medical Showcases Premium ICU Ventilator and Electronic Anesthesia Workstation at MEDICA 2021

- MESI Demonstrates Revolutionary mTABLET System at MEDICA 2021

- Microlife Presents the Only Blood Pressure Monitor with Integrated AFIB Detection at MEDICA 2021

- Innovative Health Presents Its Breakthrough Versatile and Low Cost Non-Electric Infusion System at MEDICA 2021

- Huntleigh Exhibits Range of Vital Signs Monitoring Solutions at MEDICA 2022

- Owen Mumford Presents Cutting-Edge Capillary Blood Sampling Devices for POC Testing

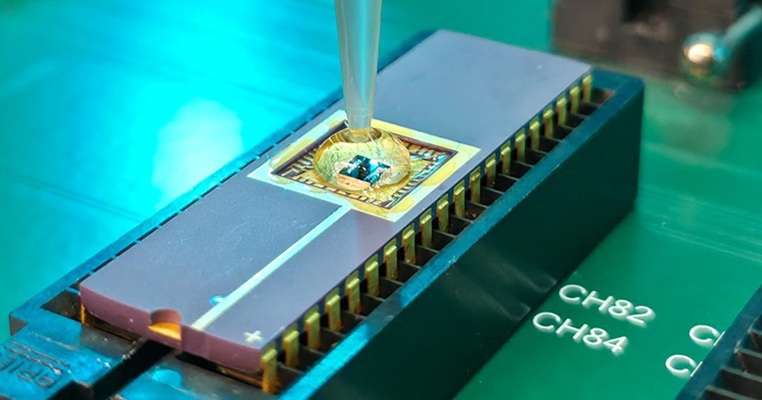

- Noul Demonstrates AI-Driven On-Site Diagnostics Platform at MEDICA 2022

- KUKA Presents Robot-Based Assistance Systems at MEDICA 2022

- Heyer Medical Exhibits State-Of-The-Art Ventilators, Anesthesia Workstations and Surgical Lights

- LG Electronics Exhibits High Resolution Monitors for Surgery and Medical Diagnosis

- Advantech Demonstrates High-Performance Healthcare Systems and Solutions

- MAVIG Highlights X-Ray Protective Clothing and Suspension Systems for Medical Equipment

- EIZO GmbH Presents New 4K Visualization Solutions for Operating Room

- OptoMedic Showcases World of Fluorescence Endoscopy Technologies

- Norav Medical Demonstrates Advanced ECG Solutions

- MAVIG Highlights Latest Innovations in X-Ray Protection and Medical Suspension Systems

- EndoSemio Features Wireless Endoscope Tracheostomy Kit for Advanced Minimally Invasive Procedures

- Brain Navi Demonstrates First Autonomous Surgical Navigation Robot for Neurosurgery

- Winners Announced of the 14th MEDICA Start-up Competition

- Hurotics Demonstrates Advanced Gait Rehabilitation Exosuit at MEDICA 2025

- CETA Testsysteme Brings Advanced Leak and Flow Testing Technologies to MEDICA 2025

- Surgical Holdings Highlights Growth and Collaboration as Part of the Stille Group at MEDICA 2025

- WEGO Medical Brings Advanced Blood Management and Surgical Technologies to MEDICA 2025